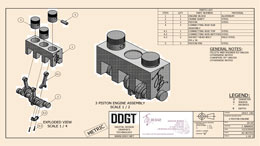

3 Piston Engine

The Engine project was modeled in Autodesk Inventor. It was then customized for the 3D printer by adding tolerancing and spacing between the parts, as well as adding the handle and the base. The 3D printer prints the assembly as one part, using a disolvable support material to keep spacing between the parts. This project allowed me to use new skills in Inventor, as well as keep up the knowledge we learned in the 3D printing class, DDGT 130.

|

|

|

| 3 Piston Engine View 1 | 3 Piston Engine View 2 | 3 Piston Engine Working Drawing |